7 S shop drilling tools supplier

Dedicated to being your preferred supplier of rock drill products

Available

Available

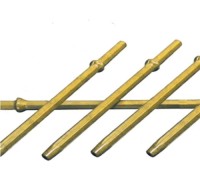

Integral carburizing taper brazing is to increase the carbon content of the surface layer of taper brazing through the carburizing process, thereby improving the surface hardness and overall strength and increasing the service life of taper brazing. Compared with conventional taper drilling, the overall carburizing taper drill rod has higher strength and better wear resistance. Under the same industrial and mining conditions, the life of the overall carburizing taper brazing is several times

Integral carburizing taper brazing is to increase the carbon content of the surface layer of taper brazing through the carburizing process, thereby improving the surface hardness and overall strength and increasing the service life of taper brazing. Compared with conventional taper drilling, the overall carburizing taper drill rod has higher strength and better wear resistance. Under the same industrial and mining conditions, the life of the overall carburizing taper brazing is several times that of the ordinary taper brazing.

Taper degree:4°46’, 6°, 7°, 11°, 12°

Shank specifications:Hex.19mm, Hex. 22mm, Hex.25mm

In addition to the conventional drill pipe length, our company can customize the product length according to customer needs.